A world of new products for asparagus

Corhize

A tool to aid decision-making

Corhize is offering Aquatech, a capacitive sensor that allows temperature measurements in the ground every 10 cm to which is added a free sensor on the surface to give the temperature under the mulch. In addition to water consumption, horizon by ground horizon, the probe allows better management of plastic films. The probe can be connected to a platform with an asparagus-specific module, Aspaview, with values to estimate the risk of burns, flowering, predicting performance at Day+1 and Day+2, calculating hours of cold and degrees days.

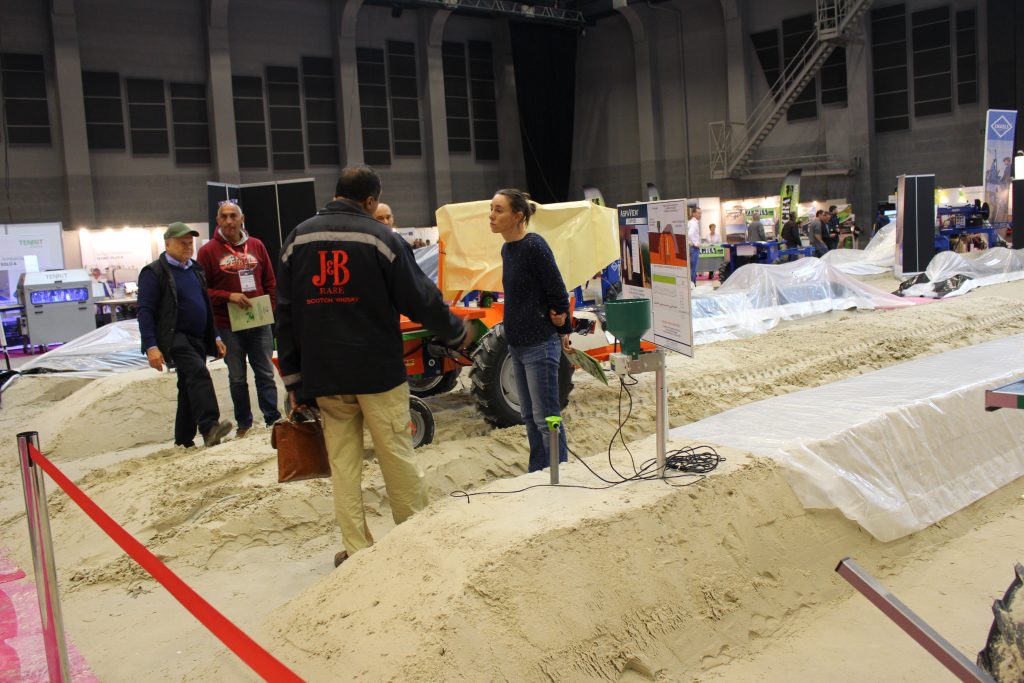

Base

Base

Solar battery recharging

Sellande by Base offers a charging system not connected to the electrical grid from photovoltaic panels on harvest assistance machines. According to the manufacturer, the power generated of 400 watts prevents the batteries from being recharged daily and limits their premature wear. For this increase in range, Base offers a kit for existing machines with different purchasing options.

Cyklop

Tying and labelling bunches

Cyklop offers the Elastobinder: a machine that binds asparagus bunches with two thin elastic bands (Stepper ®) paired with a label printer. The machine combines the two operations at the same time and can fix 20 links per minute. According to users, the kit is easy to set up. The printer can use pre-printed labels but also ensure full printing with barcode and in several languages.

Naturagriff

Naturagriff

Mechanical weeding by brushing

Already a specialist in mechanical weeding in arboriculture, now offers a machine specifically for asparagus cultivation. The machine is mounted on a pendulum frame and a hydraulic power pack rotates and controls the brushes. Each brush is independently adjustable for tilt, gauge and depth of work. The machine allows weeding right up to the edge of the plastic and to the sides of the mound. It can work between 10 and 15 km/h.

Jautrou

Makes bunches more easily

Rapido Bottes, built by Jautrou, makes it possible to make bunches from a circular tray mounted on an electric motor. A gauge allows the shaping and weighing of the bunch. The system which is simple enough for small organisations to implement, allows 1 to 4 people to work and ensure the manufacture of 800 bunches per hour. The company also offers a cover to protect the crates from wind and sun to limit the dehydration of asparagus as well as a soaking system for soaking the crates in water.

Farmax

Farmax

Deep ground working

The Dutch manufacturer Farmax offers a “special asparagus” spader allowing working on a width of 1.60 m and at a depth of 0.60 m. The machine replaces ploughing and avoids creating a “sole.” It ensures good aeration of the soil and a homogeneous mixture of organic material inputs favourable to the establishment of the crop. Varying from 80 to 12 rotations per minute allows it to advance at 2 km per hour.

Engels

For film management

Using two plastic films, one thermal and one black/white, Engels offers a combination of six positions. These options allow the films to be managed according to the weather conditions to ensure good stability of the mound temperature. The system also allows a reduction in the time spent in handling plastics and an improvement in the quality of the harvest. The company is working on a model of “management” of plastic films in order to optimize the temperature in the mound, between 18-20 degrees Celsius at the root tray level and below 35 degrees Celsius under the plastic. It should also allow the harvest rate to be determined in line with market trends.

Besnard

Besnard

Improved calibration machine

Besnard has improved its electronic washing/calibration line with the addition of a water jet just before the spear cutting blade. This adaptation allows for better cutting quality and protects teeth from premature wear. A foam wheel also allows for better maintenance of the asparagus as it is cut. At the other end of the chain, a new, more intuitive and personalised control screen makes it easier to adjust the machine. An internet connection also allows remote adjustment and troubleshooting.

Koppert

Biocontrol against asparagus beetle

Koppert offers several bio-solutions for the cultivation of asparagus including Capirel: composed of auxiliary nematodes to fight the asparagus beetle, Crioceris asparagi. Capirel’s formulation sprays auxiliaries on vegetation where they seek and kill larvae. +Squad is an additive proposed by Koppert to optimize the effectiveness of Capirel by delaying dehydration of nematodes and increasing the duration of their effectiveness. Trianum-G, a bio-control fungicide based on Trichoderma harzianum strain T22 is also proposed for the facilitation of crown implantation and prevention of the development of soil pathogenic fungi (approved General Treatments against Pythiacs).

Reyenvas

Seven layers in one Film

The manufacturer offers a wide range of plastic films including the Rey Pro mth+. This black/white hemmed thermal film is composed of 7 layers interspersing a thermal layer inside the black and white film. According to the manufacturer, it provides 3 to 5 days of precocity and its thickness (175 microns) improves its duration of use reducing the problem of recycling (less waste/tax). Reyenvas is also innovating by offering Rey Pro nature a green/white hemmed film which has the same advantages as all opaque two-tone films, while improving its integration into the landscape and reducing its visual impact.

Harlander

Harlander

WEEDING THE SIDES OF THE MOUNDS

The SDS 70 front-mounted tine harrow has been designed to mechanically weed both sides of asparagus mounds. This 2.20 m wide kit is adjustable to adapt to the height variations of the mounds (thanks to its central wheels), their width (with a hydraulic system). Springs reinforce or decrease the pressure of the crowns on the mound.

THEILMANN

CLEAR THE ASPARAGUS

This prototype wire brush cutter, 5 to 6 mm in diameter is for use on asparagus and berries. It operates between 6,000 and 8,000 rpm at a speed of 5 km/h and at an adjustable angle of attack. It leaves behind vegetation of two to three centimetres. The large holes drilled in the protective plate of the work head evacuate air which would otherwise flatten vegetation to the ground and decrease the efficiency of the passage.

Hepro

Hepro

Peeling and fresh cut machine

Hepro offers a compact vertical white asparagus peeler which allows for an “industrial quality” approach. The machine peels up to 2000 asparagus per hour. It can be used as a base for the use of the Hepro RSS, which allows white or green asparagus to be cut into cylindrical chunks. The pieces are cut by a fixed knife block. The head size is about 20 mm or 25 mm (standard version). Middle and end head pieces can be removed separately on request. The cutting of asparagus allows mixtures, white/green, in sachets.

Tenrit

cutting machine

The TAC70/R is a specialised cutting machine for asparagus. It is used for cutting asparagus into cylindrical chunks with asparagus which has already been peeled. The machine allows to cut the asparagus between 1 and 7 cm and the cut can be straight or diagonal. This machine is especially suitable for direct sale and customers are given the chance to consume asparagus differently (wok, pie, soup, etc.).

Strauss:

Strauss:

One sorting machine for all asparagus

The Optisort G-Series from Strauss is the most preferred asparagus sorting machine. Different customised machine sizes allow the processing of white and green asparagus by one machine. To prepare the asparagus for the optical sorting, first it is cut to a certain length by a sophisticated aligning and knife system, developed through long experience. Afterwards it is cleaned with a lot of water at very low pressure. Low water consumption is achieved through recycling. Then the asparagus is singled and transported individually to the optical quality recognition unit in its own cup thus avoiding incorrect classifications and, from there, to the appropriate collecting container, subdivided into different quality levels. Optisort G-Series methodology allows for every piece of asparagus to be individually checked.